AMO and Photonics Industry Leaders Partner to Advance PIC Technology with Plasmonics

EU Project PLASMOfab Successfully Completed

May 2019 – The research project PLASMOfab funded by the EU innovation program Horizon 2020 has been successfully completed to enable mass manufacturing of high-performance plasmo-photonic components. Launched in 2016, the project has brought together leading industrial partners and top-ranked academic and research institutes in the photonic integrated circuit (PIC) and opto-electronics value chain, including AMO GmbH.

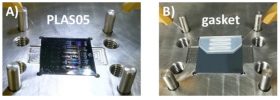

The three-year research project has significantly advanced the state of the art in PICs and CMOS-compatible plasmonics for optical data communications and biosensing for point-of-care applications. PLASMOfab has developed CMOS-compatible plasmonics to consolidate advanced PICs with electronic ICs in volume manufacturing. The project focused on CMOS-compatible metals and photonic structures that are harmonically co-integrated with electronics using standardized CMOS processes. As part of project validation, the PIC platform was used along with advanced peripherals to develop predominant functional modules with unprecedented performance.

A key project achievement was the development of a groundbreaking ultra-compact plasmonic transmitter, which has a footprint of 90 x 5.5 µm² to transmit 0.8 TBit/s (800Gbit/s) through 4 individual 0.2 TBit/s transmitters. The project also demonstrated CMOS-compatible plasmonic waveguides with the lowest possible losses, as described in Nature’s Scientific Reports in September 2018.

“PLASMOfab’s main goal has been to address the ever increasing needs for low energy, small size, high complexity and high performance mass manufactured PICs,” said Nikos Pleros, assistant professor at the Aristotle University of Thessaloniki, Greece. “We have achieved this by developing a revolutionary yet CMOS-compatible fabrication platform for seamless co-integration of active plasmonics with photonic and electronic components.”

As a result of the PLASMOfab research, two new companies have been launched to commercialize the new technologies:

- bialoom Ltd. will further explore plasmo-photonic biosensors in multichannel and high-sensitivity point-of-care diagnostics by combining plasmonic sensors with integrated Si3N4 photonic functionalities, electrical controls, biofunctionalization techniques, and microfluidics.

- Polariton Technologies Ltd. specializes in new photonic and electronic technologies for the testing, sensing, and telecommunications market. Their energy efficient and low-footprint plasmonic modulator will convert microwave signals to optical signals.

“We expect that further development of CMOS-compatible plasmonic components with CMOS fabrication processes and photonics technologies will demonstrate plasmonics’ clear advantages in PICs,” said Dr. Dimitris Tsiokos, principal researcher at the Aristotle University of Thessaloniki. “When the best of all three worlds of plasmonics, photonics, and electronics converge in a single integration platform, PICs with unprecedented performance and functionality will be realized, targeting a diverse set of applications and industrial needs while meeting mass production requirements.”

A first major step towards mass production is the creation of a R&D process design kit (PDK) for the developed fabrication process. This has been established successfully at AMO and is offered to customers via the AMO foundry services.

“We are pleased to have been working closely with the partners in this project and especially with AMO and ams to develop R&D PDKs for the new PLASMOfab integration technology,” said Twan Korthorst, director of Synopsys’ Photonic Solutions. “The PDKs are supported by our PIC design platform, which provides the industry’s only full design flow from photonic device level to PIC to system levels.”

About PLASMOfab

PLASMOfab was a three-year collaborative project on CMOS-compatible photonic, plasmonic and electronic integration that brought together ten leading academic and research institutes and companies: the Aristotle University of Thessaloniki (Coordinator) (Greece), ams (Austria), AMO (Germany), PhoeniX Software, now part of Synopsys (Netherlands), ETHZ (Switzerland), Micram (Germany), University of Saarland (Germany), Austrian Institute of Technology (Austria), University of Burgundy (France) and Mellanox (Israel). The project was launched in January 2016 and it was funded by the European Union’s Horizon 2020 ICT research and innovation programme under grant agreement No 688166. To learn more about the results of PLASMOfab visit http://www.plasmofab.eu/.

About AMO:

AMO as a research oriented company closes the gap between university research and industrial application. For this purpose AMO identifies those topics from basic research that seem particularly suitable for industrial implementation and demonstrates these in application-oriented nanotechnology. In joint projects like PLASMOfab and bilateral cooperation, research and development results are transferred to industry for maintenance and creation of jobs. Thus nanotechnology is expected to provide considerable potential for application areas such as information technology, biotechnology and environmental technology. Headed by Prof. Max Lemme, AMO operates a state-of-the-art 400 m² cleanroom. Furthermore AMO offers a range of services from consulting to prototype development.

Based on this please find the press release by Synopsys: https://news.synopsys.com/2019-05-01-Synopsys-and-Photonics-Industry-Leaders-Partner-to-Advance-PIC-Technology-with-Plasmonics