How nanotechnology can help solving water shortage problems

Supplying water to cities and towns has become an increasingly serious problem in many parts of the world. In many cases, long-term solutions must necessarily include wastewater reuse, but establishing a closed-loop water supply system is an extremely challenging problem, which involves a lot of political, economical and technological challenges. One of the major problems is the cost of the processes needed to remove tenacious organic contaminants from water – and this is where nanotechnology can help.

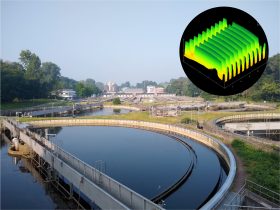

Wastewater treatment plant in Aachen-Soers (Picture © RWTH Aachen University, Vera Kohlgrüber). In the inset, an Atomic Force Microscope (AFM) image of the nanoantennas. The length of the antennas is about 6 µm, their width and the spacing between them is below 1 µm.

One of the most effective ways of getting rid of organic contaminants are treatments that use high-energy UV-light to generate highly reactive hydroxyl radicals (·OH), which in turn decompose contaminants into harmless compounds. The major downside of this approach is its energy cost, which is currently far too high for municipal wastewater treatment. “The situation can be drastically changed if we use nanotechnology – or more precisely plasmonic nano-antennas – to exploit light more efficiently”, says Ulrich Plachetka, leader of the Sensor Technology Group at AMO GmbH.

In fact, most of the costs of the treatment are related to the production of the high-energy UV photons. Plasmonic nanoantennas are metallic structures with typical dimensions of a few tens or hundreds of nanometers (i.e. thousand times smaller than the width of a human hair), which allow converting the optical radiation arriving on a surface into very intense, local fields on the surface itself. “Using plasmonic antennas covered by a thin-film of photocatalysts such as Titanium dioxide (TiO2), we should be able to increase the production of hydroxyl radicals and to reduce significantly the energy cost of the process”, explains Plachetka. “Furthermore, optimizing the geometry of the antennas and of the TiO2 layer, it should be also possible to achieve good photocatalyst activity with solar light”.

These ideas are at the core of PEPcat, a project funded by Federal Ministry of Education and Research (BMBF) within the funding initiative “CLIENT II – International Partnerships for Sustainable Innovations” – an initiative aimed at opening up new markets for innovative, export-oriented German companies (particularly small and medium-sized enterprises, SME), while contributing to fight environmental degradation. PEPcat is an acronym for “Energy-efficient advanced oxidation for removal of organic substances in wastewater through plasmonically enhanced photocatalysis”, and it is a project of AMO GmbH together with the Institute for Environmental Engineering at the RWTH Aachen University, Coatema Coating Machinery GmbH, UMEX GmbH Dresden, and HOLINGER Ingenieure GmbH.

The goal of the project is to come up with a practical solution for the problem of water reuse in the Beijing area, where water-shortage problems are already a dramatic reality (about 470 million m3 of water missing in 2018). “Our project focuses on the region of Beijing, but the solutions that we are developing can be adapted and extended also to other metropolitan areas in other parts of the world”, says the project coordinator Prof. Thomas Wintgens, director of the Institute for Environmental Engineering at RWTH. “What we want to show is that direct water reuse is technically feasible and that high water quality is achievable”.

“What I find very exciting about this project”, says Plachetka, “is that it brings together all the expertise needed to move from an abstract idea to the solution of a concrete problem. As AMO, we contribute our experience in plasmon engineering and nanostructuring for developing the plasmonically-enhanced photocatalytic elements that are the core aspect of PEPcat technology. We are then collaborating with Coatema – a family company expert in coating, printing and laminating plants – to develop a pilot system for transferring the nanostructures developed in our clean room to large scale. This is crucial to ensure that our technology is scalable and economically viable. Furthermore, we are collaborating with UMEX and the Institute for Environmental Engineering of the RWTH Aachen University to develop prototype reactors to test the degradation performance of the new photocatalytic elements and to optimize it.”

UMEX is a small company specialized in the planning and fabrication of UV systems, lamps and reactors for water treatment plants. The Institute for Environmental Engineering at RWTH is the coordinator of the PEPcat project, and has extensive experience in all aspects of wastewater management, including civil and process engineering, environmental technology, biology and chemistry. The other German partner of the project is HOLINGER Ingenieure GmbH, a leading engineering company specialized in sustainable solutions related to water, constructions and infrastructures.

“Nanotechnology is a key enabling technology for addressing many of humanities global challenges”, says Prof. Max Lemme, Director of AMO GmbH. “This project is a good example of how it provides solutions that are not feasible with conventional approaches. At AMO, we have been developing nanostructuring techniques for years. It is extremely rewarding to see how the results of our long-term research form the basis of this very applied research project that may have far-reaching implications for the sustainability of cities.”

PEPcat is funded by the Federal Ministry of Education and Research (BMBF), under grant agreement Nr. 02WCL1519B.

Comments are closed.